Palgio – CNC milling services

Palgio offers CNC milling services for aluminum and plastics. We operate on a modern 3-axis CNC plotter of Polish production. We have the capability to create precise products with the accuracy desired by the customer. We specialize in milling relatively small-sized and complex-structured components. We handle both prototype and serial orders. Quotations are provided based on email inquiries sent to: office@palgio.pl.

Useful information related to CNC milling services – info – blog

Machine-made products are known for their high repeatability and dimensional accuracy. We offer CNC milling services on a professional CNC machine dedicated to processing aluminum and plastics. Learn more about our CNC services or send inquiries to office@palgio.pl.

How to prepare a model for CNC milling services? The specific features of your design can impact the higher cost of production.

Specific shapes in a given 3D model can significantly impact the cost of CNC milling services. It’s essential to understand the basic principles of designing 3D models for machining and, after creating the initial design, optimize it.

Negative angles can only be machined on a 5D milling machine, which has a much higher purchase cost than a conventional 3-axis machine, making the hourly labor cost more expensive.

Wall inclinations can be machined on a 3-axis machine, but for proper accuracy, the machine must make numerous movements with a step smaller than 0.1mm, significantly extending the machining time and raising the cost.

Micro-milling – shapes that require the use of cutters with a diameter of 1mm or smaller significantly prolong the machining process. When performing CNC milling using micro-mills, the operator must significantly reduce the machine feed rates and cutting depths to avoid damaging such a delicate tool.

Milling elements from multiple sides. Each time the element is rotated, it needs to be re-referenced. The precision of this operation affects the overall displacement of the entire machined surface relative to the previous setup.

Defining narrow tolerances for the entire model instead of individual walls. If a specific dimension is critical for the model, set a narrow tolerance for it and assign looser tolerances for other dimensions to be milled.

How and what to ask to receive a price quote for CNC milling service? Please provide additional details in your inquiry.

CNC milling service is a process where the client outsources the production of their designed part to an external company equipped with the necessary machinery.

The cost of manufacturing a product using CNC milling service depends on various factors, so each time the client should send an inquiry along with the computer model they want to produce.

The most popular way to receive a quote is to send an inquiry via email with the attached file of the part to be produced. The inquiry should be detailed to enable precise pricing: it should include a description of the material from which the part is to be made (PA6, PLA, PA, POM, etc.), the quantity of parts to be produced (unit cost decreases with the increase in quantity), and the expected accuracy of production (the narrower the dimensional tolerance, the higher the cost of manufacturing the part). The cost of producing a part with an accuracy of 0.01mm can be several times higher than producing the same part with an accuracy of 0.1mm.

Upon receiving the inquiry, the machining service provider must analyze it: estimate the time required for production, assess the complexity of the part – whether a simple 3-axis CNC milling machine is sufficient for its production, or if multiple types of machines need to be used. The analysis of the inquiry typically takes from a few hours to 48 hours. After this period, the client will usually receive information about the cost of production and, if accepted, an estimated delivery date. If the client approves the quotation, the company specializing in CNC milling services adds the task to the queue for execution.

Machines used for CNC milling services. Will having a basic machine be enough to meet customer expectations?

The most popular machines used for providing CNC milling services are three-axis machining centers with automatic tool change. The cost of such a machine starts from around 100,000 PLN, and top versions can exceed this amount more than 10 times. A 3-axis CNC milling machine allows rough and finishing machining in 2D, 2.5D, and 3D formats. However, this type of machine cannot handle negative angles, which is possible for a 5D milling machine – an extended version of the machine with a tilted spindle or, depending on the solution, a tilted worktable. With this modification, a 5D milling machine has virtually unlimited possibilities for creating details.

Oval products are created on a CNC lathe, where the machine rotates the processed detail around its axis and applies and moves the cutting tool at the appropriate places to achieve the desired dimensions.

Since the 2000s, modern CNC machines called CNC hybrids have been available on the market. This machine combines a CNC machine with a 3D printer. The principle of this solution is to add rough material and then machine it. This method allows saving a considerable amount of material and shortening the processing time. The machine adds material with a slight excess, which is quickly removed by the milling part of the machine.

A cut-off saw is a machine on which the operator cuts a piece of material needed for the service from a larger sheet – the blank.

Laser – a CNC machine with a CO2 or fiber laser source. Machines of this type have very high dynamic movements and allow processing steel and aluminum sheets of various thicknesses.

Waterjet – a machine for cutting thick steel sheets, larger than 30mm. A waterjet machine has much slower feeds than a laser CNC cutter, but it allows processing steel over 100mm in thickness.

CNC Plasma – a plasma cutting machine used for sheets ranging from 0.1mm to 10mm in thickness. Plasma cutting takes much longer than laser processing. The processing time is compensated by the price of the machine, which can be even 10 times lower than a laser cutting machine.

CNC milling techniques on a 3-axis machine. Types of movements performed by the machine

Surface planning – In most cases, the first operation performed by the CNC milling machine. This operation aims to level the external surface of the workpiece and trim it to the required dimensions for further processing. It is carried out with a relatively large diameter end mill.

Sample surface planning parameters for milling aluminum (PA6):

End mill diameter: 10mm

Cutting depth: 1.0mm

Cutting width: 9.0mm

Spindle speed: 19000 RPM

Feed rate: 2300 mm/min

Profile

The operation used to create a free-standing wall. This movement can be performed simultaneously (movement direction consistent with the spindle rotation) or in the opposite direction. Additionally, in this type of movement, milling is distinguished between roughing and finishing. In rough milling, the mill leaves material allowance (approximately 0.1 times the tool diameter), which is then removed in the finishing pass. The finishing pass allows achieving the precise intended dimensions and significantly improves the surface quality.

When milling profiles, CNC milling machines typically use G-codes such as: G00, G01, G02, G03.

Sample CNC Milling Parameters – Profile Machining (PA6)

Roughing Movement:

Tool diameter: 6mm

Cutting depth: 3mm

Cutting width: 5mm

Spindle speed: 16000 RPM

Feed rate: 3000 mm/min

Finishing Movement:

Tool diameter: 6mm

Cutting depth: 16mm

Cutting width: 0.6mm

Spindle speed: 22000 RPM

Feed rate: 5000 mm/min”

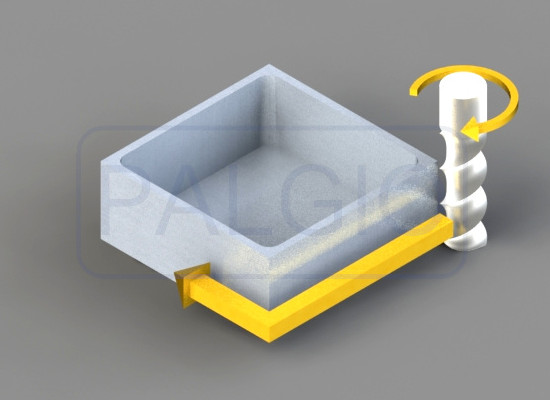

Pocket milling

The machine starts roughing from the center of the pocket and moves outward. Both parallel and counter movements are possible during roughing. After roughing the pocket, the machine proceeds to finish the pocket.

When CNC milling a pocket, the machine commonly uses G-codes: G00, G01, G02, G03.

Sample roughing parameters (PA6):

Tool diameter: 6mm

Cutting depth: 3mm

Cutting width: 5mm

Spindle speed: 16000 RPM

Feed rate: 860 mm/min

Drilling

If CNC milling service requires drilling in the material, it is done as the first operation – before milling.

Numerically controlled milling machines can perform drilling of multiple holes in a cycle. In this case, parameters for the cycle are set in the G-code: drilling type, speed, depth, and positions of each hole. The machine, when starting the cycle, memorizes the parameters of that cycle and applies them to drilling at each specified location within the cycle.

The basic drilling type is controlled by the G81 command. In this motion, the machine starts drilling and drills to the specified depth in one go.

For larger drills or significant drilling depths, it’s advisable to use the G83 command. In this type of motion, the machine drills with a tool retraction and material chip breaking. The parameters given with the G83 command allow adjusting how far the drill retracts at each chip break.

Engraving

The execution of a 2D engraving requires the use of a special type of mill with a sharp cutting edge. Depending on the depth of engraving and the angle of the cutter in the mill, the operator can create an engraving with the desired line width. The machine performing the engraving typically utilizes G-codes such as G00, G01, G02, and G03.

Benefits of Machining Services

The selection and purchase of the appropriate size of the material block are the responsibility of the service provider

The service provider selects the correct machining parameters based on their experience and knowledge.

The service provider maintains the good condition of their machinery and tools, conducting regular inspections and repairs.

Leveraging their extensive experience, the service provider manufactures products according to the client’s specifications.

Intense competition leads to a decrease in CNC milling service prices.

High repeatability – machine-milled products will be consistent in dimensions and appearance.

Efficiency – short production time for multiple components.

High precision – products maintain the specified tolerances.

Automation of the process – the CNC milling machine automatically changes tools during operation.

Disadvantages of CNC milling services that clients often do not notice

- Machine breakdowns can lead to an extension of the order completion time.

- Operator or toolpath designer errors can result in incorrect execution of the detail, which the client will have to report as a complaint.

- The client has little influence on expediting the completion time. Few companies offer services within a few hours. In most cases, companies providing CNC milling services have a queue of tasks for several working days ahead.

- Waiting for the delivery of the manufactured component – shipping the item to the client takes a minimum of one day.

- The current service provider may not have the appropriate machinery for a new order, forcing the client to look for another supplier.

Gkod used by the machine

A CNC milling machine can execute a planned detail as long as it receives an appropriate program that is understandable to the machine. The standard code understood by the machine is G-code. It is a set of movements prepared by the operator, which the milling machine will perform during CNC milling services to create the desired product.

The most common G-code commands include:

G00 – Rapid positioning to a specified position at maximum speed.

G01 – Linear movement to a specified position at a given speed.

G02 – Circular interpolation to a specified position clockwise.

G03 – Circular interpolation to a specified position counterclockwise.

G04 – Dwell (temporary stop).

G80 – Drilling to a specified depth.

G83 – Peck drilling to a specified depth with tool retraction.

G90 – Absolute positioning – after this command, the positions specified in the G-code are global machine coordinates relative to the base.

G91 – Incremental positioning – after this command, the positions specified in the G-code indicate how much the machine should move in a specific axis from its current position.